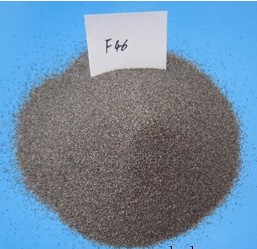

BFA Grits Brown Corundum for porous ceramics

Brown fused alumina (BFA) grits are engineered specifically for the production of high-performance porous ceramics, offering a unique combination of thermal stability, mechanical strength, and controlled porosity. Sourced from premium bauxite and processed under strict quality control, BFA grits ensure consistent performance in demanding applications such as filtration, insulation, and structural components.

Related parameters:

| Product Name | BFA Grits Brown Corundum |

| Material | Bauxite |

| Color | Brown |

| Standard | FEPA JIS |

| Grade | A/B/C |

| Mohs Hardness | 9.0 |

| Bulk Density | 1.53-1.99g/cm3 |

| Specific Gravity | 3.95 g/cm3 |

| AVAILABLE SIZES | |

| USED FOR REFRACTORY | 0-1MM 1-3MM 3-5MM 5-8MM -100MESH -200MESH -320MESH |

| USED FOR BLASTING | #8 #10 #12 #14 #16 #20 #24 #30 #36 #46 #54 #60 #70 #80 #90 #100 #120 #150 #180 #220/F8 F10 F12 F14 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220 |

| USED FOR POLISHING | #240 #280 #320 #360 #400# #500 #600 #700 #800 #1000 #1200 #1500 #2000/F230 F240 F280 F320 F360 F400 F500 F600 F800 |

Key Features & Benefits:

- High Purity & Thermal Resistance: With an Al₂O₃ content exceeding 95%, BFA grits withstand temperatures up to 1,850°C, making them ideal for refractory and high-temperature ceramic applications.

- Controlled Particle Size Distribution: Available in standard and custom grit sizes (F12–F220), BFA enables precise pore formation, enhancing filtration efficiency and structural integrity.

- Excellent Mechanical Strength: The angular grain structure provides superior bonding with ceramic matrices, improving wear resistance and load-bearing capacity.

- Chemical Inertness: Resistant to acids, alkalis, and molten metals, BFA-based porous ceramics maintain performance in harsh environments.

Applications:

BFA grits are widely used in manufacturing:

- Molten Metal Filters: Remove inclusions from aluminum, copper, and steel alloys.

- Thermal Insulation: Create lightweight, heat-resistant panels for furnaces and kilns.

- Catalyst Supports: Provide high surface area and stability for chemical reactors.

- Bioceramics: Serve as scaffolds for tissue engineering due to biocompatibility.

Quality Assurance:

Each batch undergoes rigorous testing for chemical composition, hardness (Mohs 9), and particle morphology, ensuring compliance with international standards (ISO 8486, ASTM C618). Custom blending and technical support are offered to meet specific project requirements.

BFA grits empower manufacturers to develop advanced porous ceramics with enhanced durability, efficiency, and cost-effectiveness. Contact us to discuss tailored solutions for your application.